|

Item |

Typical Value |

Description |

|

Hardness (Shore A) |

55 ± 5 |

Balanced flexibility and sealing strength |

|

Tensile Strength |

≥ 7.0 MPa |

Ensures stable performance during vacuum lamination |

|

Tear Strength |

≥ 28 N/mm |

Excellent tear resistance, durable in repeated use |

|

Elongation at Break |

500–650% |

High elasticity, prevents breakage under stress |

|

Thickness |

2.0–3.0 mm (customizable) |

Standard thickness, other sizes available |

|

Width |

up to 3800 mm |

Suitable for large-format laminated glass |

|

Surface Type |

Smooth / Textured |

Optimized for air evacuation and anti-slippage |

|

Color |

Transparent, Grey, Rust Red (customizable) |

Multiple options for different applications |

|

Service Life |

2000+ cycles |

Excellent heat resistance and durability |

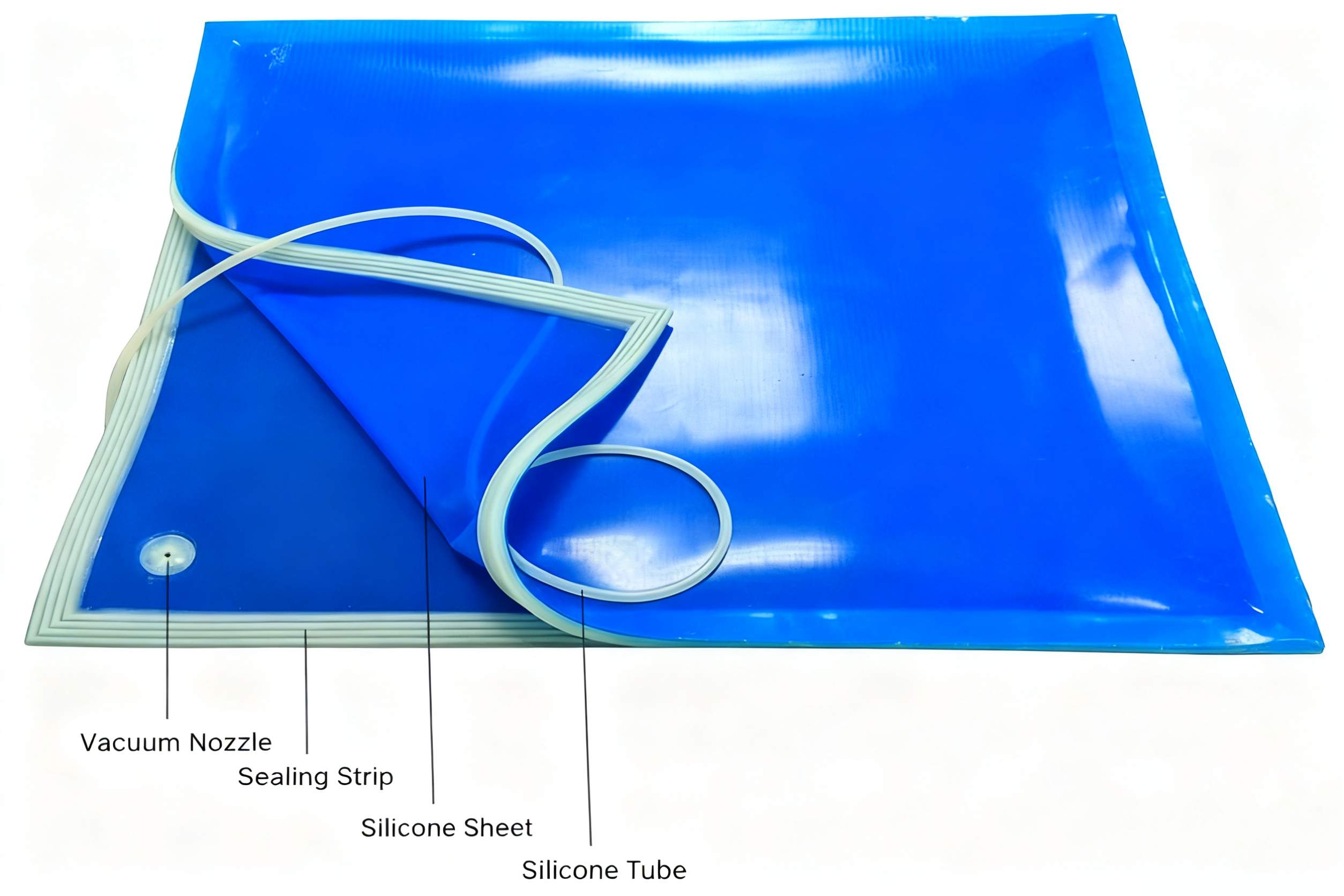

Vacuum Silicone Bag

Product Features:

- High Heat Resistance – Made of premium silicone rubber, it can withstand repeated heating cycles without deformation or degradation.

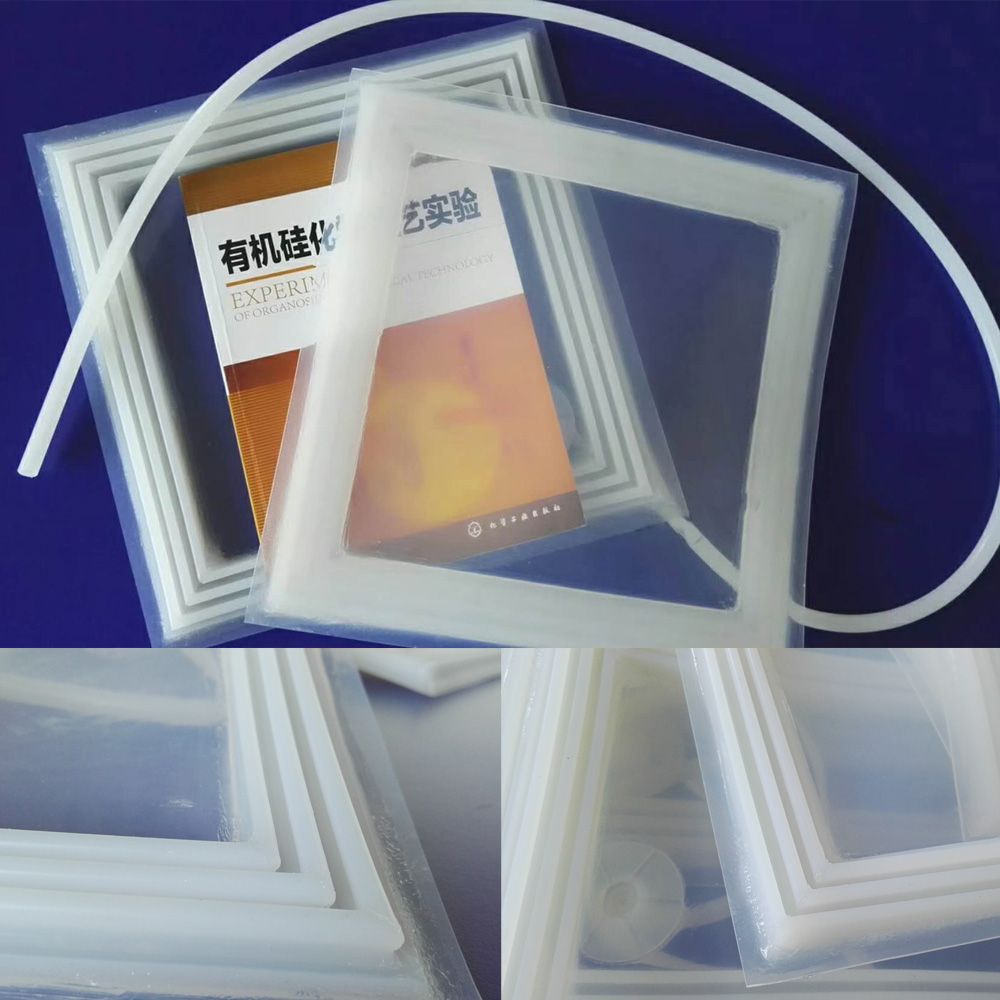

- Excellent Sealing Performance – Durable sealing strips ensure airtight vacuum conditions, preventing air and moisture infiltration.

- Strong Mechanical Properties – High tensile strength, tear resistance, and elasticity provide long service life and stable performance.

- Optimized Surface Design – Available in smooth or textured finishes to improve air evacuation and prevent slippage during lamination.

- Reusable and Cost-Effective – Designed for multiple production cycles, reducing replacement frequency and overall processing costs.

- Wide Application Range – Suitable for architectural laminated glass, decorative glass, safety glass, photovoltaic panels, and other high-end glass processing.

Product Description

Vacuum silicone bag, also known as silicone vacuum sheet or sealing belt, is a key auxiliary material in laminated glass production. It is used to create a closed vacuum environment during the lamination process, ensuring that air and moisture are efficiently removed from between the glass and interlayer film (EVA, PVB, or SGP). By combining heat and negative pressure, the silicone bag provides uniform sealing and pressure, which helps eliminate bubbles, improves adhesion, and guarantees the optical clarity and safety performance of laminated glass.

Made from high-quality silicone rubber, the product offers excellent heat resistance, tensile strength, tear resistance, and elasticity, allowing it to withstand repeated heating and cooling cycles without deformation or damage. The smooth or textured surface options enhance air evacuation and prevent slippage, while the durable sealing strip maintains reliable airtight performance. Vacuum silicone bags are widely applied in architectural laminated glass, decorative glass, safety glass, photovoltaic panels, and other advanced glass processing fields. With stable quality and long service life, they are an essential tool for achieving high-end laminated glass solutions.

Product Application

- Flat Laminated Glass Production

Used in curtain walls, windows, doors, and other flat glass applications, ensuring strong adhesion, clarity, and durability.

- Curved & Special-Shaped Glass

Applicable for bent, curved, and double-curved laminated glass. Patents also highlight its use in complex glass shapes, ensuring reliable sealing and lamination.

- Safety & Explosion-Proof Glass

Designed for products requiring anti-shatter and explosion-proof performance, commonly used in public buildings, transportation facilities, schools, and hospitals.

- Decorative Glass with Embedded Materials

Supports the embedding of fabrics, paper, colored films, or textured layers, enabling both artistic expression and functional performance. Some manufacturers emphasize its dual role in aesthetics and practicality.

- Simplified Lamination without Autoclave

Allows lamination by replacing or reducing the need for autoclaves, using vacuum + heat + sealing strips to remove air and achieve adhesion. This helps lower equipment investment and energy consumption.

FAQ

Q1: What is the function of a silicone vacuum bag in laminated glass production?

A1: It creates a sealed vacuum environment during lamination, removing air and moisture between glass and interlayer films (EVA, PVB, SGP). This prevents bubbles and ensures strong adhesion, optical clarity, and durability.

Q2: Can the silicone vacuum bag withstand high temperatures?

A2: Yes. High-quality silicone bags can typically resist temperatures up to 200–260 °C, suitable for repeated heating and cooling cycles in glass lamination.

Q3: Is the vacuum bag reusable? How long is the service life?

A3: Silicone vacuum bags are designed for multiple production cycles. Under proper operation and maintenance, they can be reused hundreds or even thousands of times, depending on process conditions.

Q4: What types of glass applications are suitable?

A4: They are widely used for flat laminated glass, curved or special-shaped glass, safety and explosion-proof glass, decorative laminated glass with embedded materials, and even lamination processes without autoclave.

Q5: What thickness and surface options are available?

A5: Standard thickness is 2–3 mm, with both smooth and textured surfaces available. Textured surfaces help improve air evacuation and reduce slippage during lamination.

Q6: How to maintain the silicone vacuum bag for longer life?

A6: Check sealing strips regularly, avoid sharp glass edges, keep the bag clean with mild detergents, and operate within the recommended temperature range to prevent damage and extend lifespan.