|

Item |

Unit |

Value / Index |

Remarks |

|

Product Name |

— |

Ionoplast interlayer (SGP)

|

— |

|

Composition |

— |

Ethylene–methacrylic acid ionomer copolymer |

Blended with functional additives |

|

Thickness |

mm |

0.76/0.89/1.14/1.52/2.28

|

Customizable upon request |

|

Width |

mm |

up to 2500 |

— |

|

Length (Roll) |

m |

100 (0.89 mm) / 50 (1.52 mm) |

Supplied in roll form |

|

Basis Weight |

g/㎡ |

~360 (0.38 mm equivalent) |

Varies with thickness |

|

Visible Light Transmittance |

% |

≥ 90 |

High optical clarity |

|

Haze |

% |

< 0.5 |

Clear visibility |

|

UV Blocking (280–380 nm) |

% |

≥ 99 |

Excellent UV protection |

|

Yellowing Index (ΔYI) |

— |

< 1.5 |

Superior anti-yellowing stability |

|

Tensile Strength |

MPa |

> 34 |

More than 2× stronger than PVB |

|

Tear Resistance |

kN/m |

> 100 |

Significantly higher than PVB |

|

Rigidity (Modulus) |

— |

5× higher than PVB |

Enhanced structural capacity |

|

Adhesion with Glass |

— |

Excellent |

Suitable for bare-edge applications |

|

Weather Resistance |

— |

Pass |

Resistant to heat, humidity, UV, and outdoor exposure |

|

Operating Temperature Range |

°C |

-20 ~ +80 |

Long-term stability |

|

Shelf Life / Storage |

— |

12–24 months in sealed packaging |

Store in cool, dry conditions |

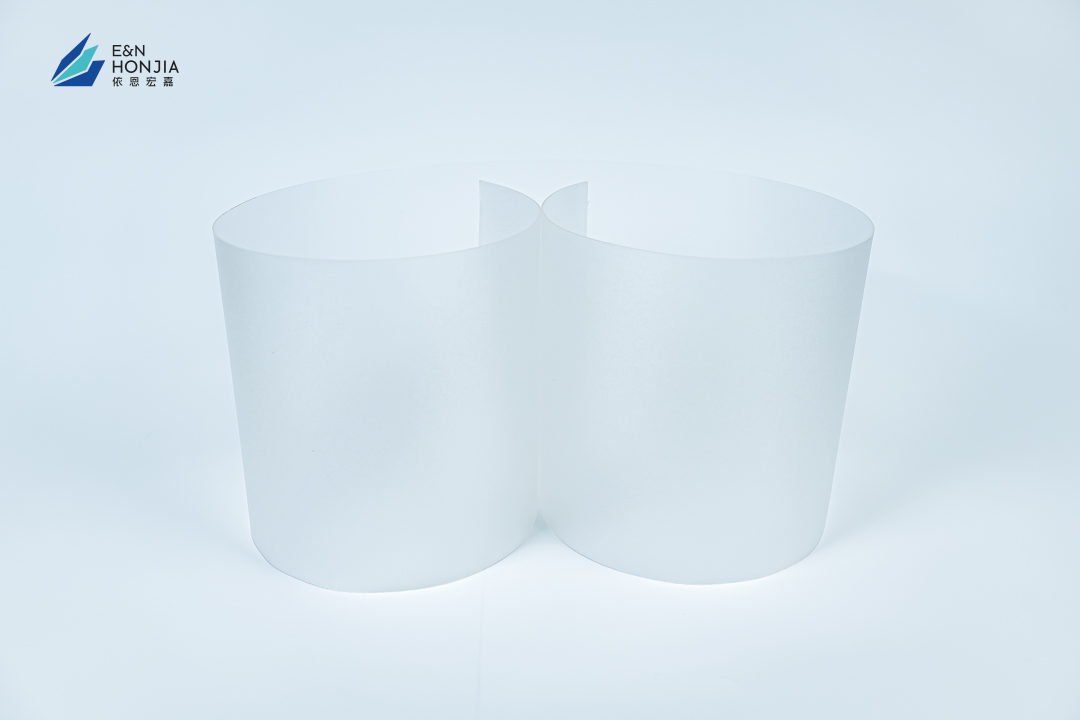

Ionoplast Interlayer(SGP)

Product Features :

1.High Strength & Rigidity

- Over 2× stronger and 5× stiffer than conventional PVB interlayers.

- Provides excellent structural performance for demanding projects.

2.Superior Optical Clarity

- Visible light transmittance ≥90% with very low haze.

- Maintains clear and distortion-free laminated glass.

3.Excellent Anti-Yellowing Performance

- Long-term stability with ΔYI < 1.5.

- Retains transparency and aesthetics even after years of exposure.

4.UV Protection

- Blocks >99% of harmful UV rays (280–380 nm).

- Protects interiors and reduces fading of furnishings.

5.Strong Adhesion & Edge Stability

- Outstanding bonding with glass and resistance to edge defects.

- Reliable performance under heat, humidity, and outdoor conditions.

6.Impact & Safety Performance

- Exceptional tear resistance and fragment retention.

- Enhances safety in case of breakage.

7.Durability & Weather Resistance

- Performs reliably under high temperature, high humidity, and extreme environments.

- Suitable for long-term outdoor applications.

8.Wide Applications

- High-rise curtain walls, skylights, glass balustrades, pedestrian bridges, bank security glazing, and other structural or safety-critical glass.

Product Description

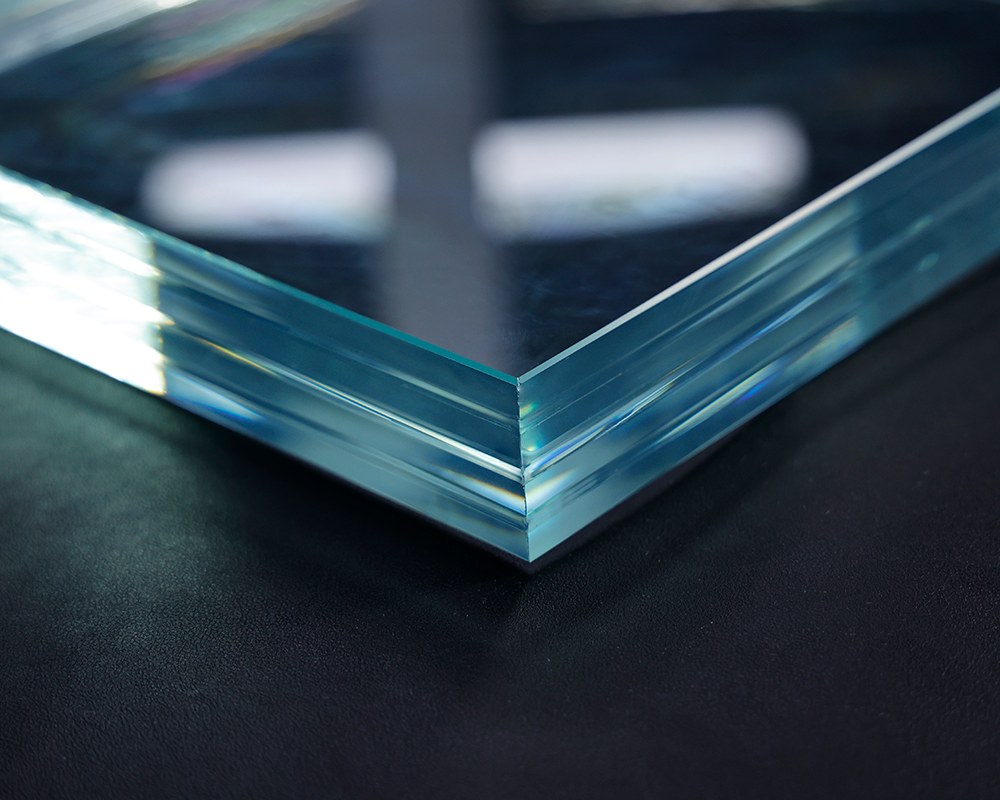

The SGP Ionoplast Interlayer from E&N HONJIA is an advanced interlayer film engineered for laminated glass applications requiring exceptional strength, durability, and safety. Compared with traditional PVB, SGP delivers over 2× the tensile strength and 5× the rigidity, providing superior tear resistance and outstanding edge stability, even under high temperature, high humidity, or other harsh environmental conditions.

SGP offers visible light transmittance ≥90% with low haze, ensuring long-lasting optical clarity. Its anti-yellowing performance (ΔYI < 1.5) guarantees stability over time, while blocking over 99% of harmful UV radiation (280–380 nm) to preserve interiors and protect occupants. With excellent impact resistance and superior glass fragment retention, SGP significantly enhances the overall safety of laminated glass.

Typical applications include high-rise curtain walls, large-span skylights, glass balustrades, pedestrian bridges, bank security glazing, and public safety glass. It is especially suitable for structural projects requiring resistance to typhoons, earthquakes, and blast impacts.

By combining exceptional transparency, mechanical strength, and long-term durability, E&N HONJIA SGP is the ideal choice for modern architectural design, ensuring both safety and aesthetics.

Processing Technolog

1.Film Handling & Storage

- Environment: 20–25 °C, 20–30% RH, cleanroom conditions to prevent moisture absorption.

- Handling: Use clean gloves or vacuum suckers; avoid folding, dragging, or heavy pressure.

- Storage: Keep sealed in vacuum packaging, store below 20 °C, RH ≤30%. Use within 24 h once opened.

- Splicing: For oversized glass, splice films and cover seams with SGP adhesive strips (6–10 mm wide, same thickness as film).

2.Glass Preparation

- Cutting: Precision cutting as per design, edges must be ground/polished.

- Cleaning: Use deionized water and automated washer; hot-air drying to remove moisture.

- Cleanliness: Assembly area should meet Class 100–1000 cleanroom standards, with positive pressure airflow.

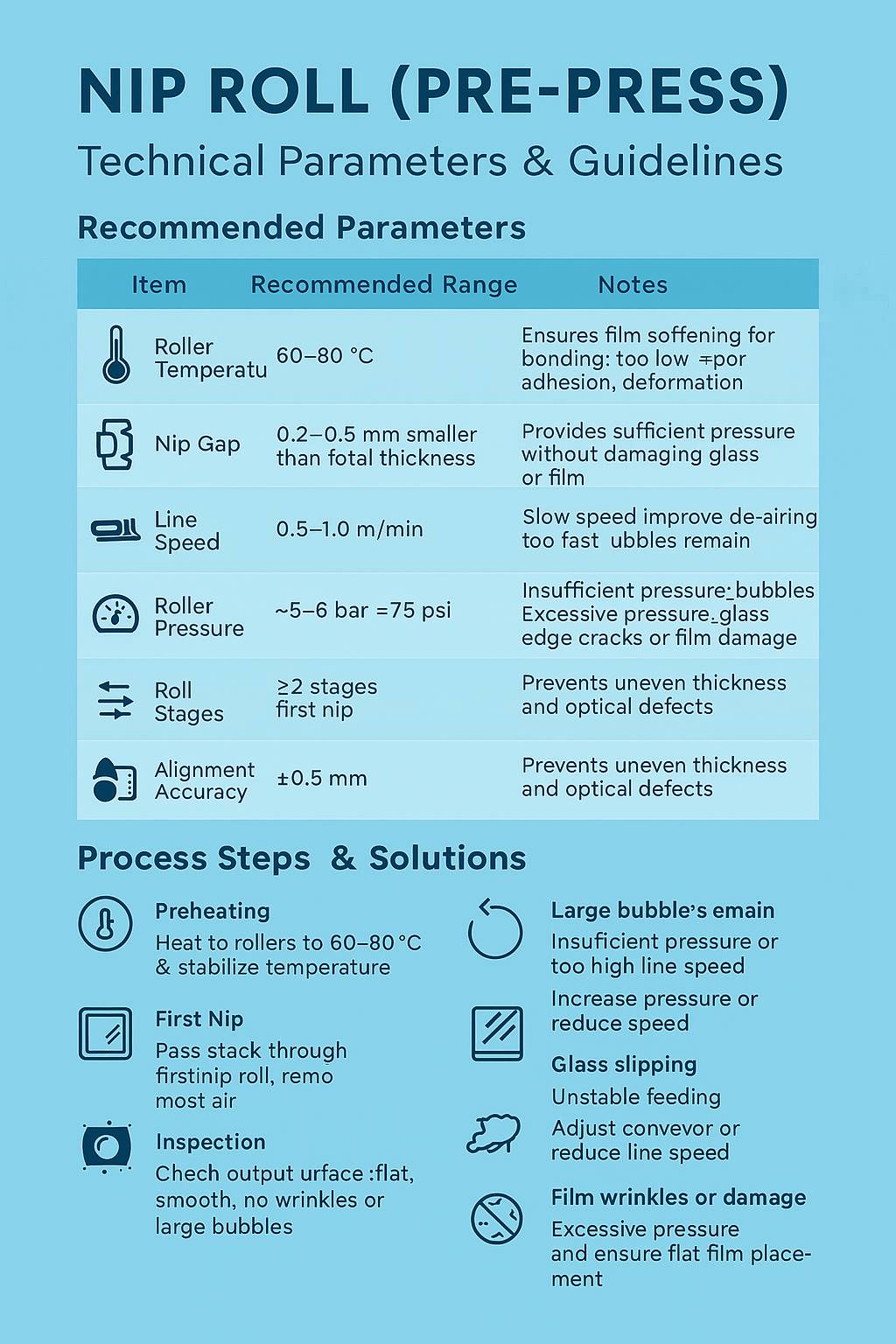

3.Nip Roll / Pre-Press

- Purpose: Pre-bond glass and film, expel most of the air.

- Parameters:

(1)Temperature: 60–80 °C

(2) Nip gap: 0.2–0.5 mm smaller than total thickness

(3) Speed: 0.5–1.0 m/min

- Steps:

(1)Feed glass-film stack smoothly into nip roller.

(2) Monitor alignment, prevent shifting.

(3) Inspect output for uniform surface, no major air bands.

- Precautions:

(1)Low pressure → residual air.

(2)High pressure → edge cracks.

(3)Dirty rollers → dents/particles.

- Problems & Solutions:

(1)Surface waves → uneven roller heating.

(2)Misalignment → adjust conveyor speed, add positioning device.

(3)Indentations → clean rollers thoroughly.

4.Vacuum De-Air Process

- Purpose: Remove residual air, prevent bubbles and delamination.

- Parameters:

(1)Vacuum: −0.85 ~ −0.95 bar

(2)Duration: 30–60 min (≥90 min for large/ thick units)

- Steps:

(1)Place stack into vacuum bag/chamber, ensure proper sealing.

(2)Place vent strips/microporous tape along edges.

(3)Pump down gradually to target vacuum.

(4)Maintain negative pressure until autoclaving.

- Precautions:

(1)Check sealing before process.

(2)Monitor pressure gauge for stability.

- Problems & Solutions:

(1)Insufficient vacuum → leaks or pump issues.

(2)Bubbles at seams → adhesive strip not covering fully.

(3)Edge bubbles → vent strips misaligned.

5.Autoclave Laminating & Curing

- Purpose: Complete crosslinking of SGP, achieve permanent bonding.

- Parameters:

(1)Temperature: 135–145 °C

(2)Pressure: 12–14 bar

(3)Holding time: 2–4 h

(4)Cooling: staged cooling, avoid quenching

- Steps:

(1)Load evenly, maintain 10–20 mm spacing.

(2)Increase temperature & pressure gradually.

(3)Monitor multiple sensors to ensure uniformity.

(4)Controlled cooling after curing.

- Precautions:

(1)Fast heating → glass breakage.

(2)Short holding → incomplete bonding.

(3)Slow cooling → haze/crystallization.

- Problems & Solutions:

(1)Local bubbles → uneven heating, adjust circulation fans.

(2)White haze → slow cooling, optimize curve.

(3)Delamination → film moisture, improve environment control.

6.Adhesive Strip (Splicing Tape) Usage

- Application: For film splicing when glass size exceeds film width.

- Materials: Same as SGP film; width 6–10 mm; thickness same as film.

- Steps:

(1)Place strip flatly along seam, fully covering it.

(2)Press gently to bond tightly, avoid wrinkles.

(3)In autoclave, strip melts & crosslinks with film, eliminating seam visibility.

- Precautions:

(1)Must be clean, dust-free.

(2)Not fully covered → seam visible/bubbles.

(3)Uneven placement → delamination at seam.

- Problems & Solutions:

(1)White seam → strip thickness mismatch.

(2)Seam bubbles → poor sealing, re-align.

(3)Visible seam → material mismatch, always use same ionoplast.

7.Inspection & Finishing

- Appearance: No bubbles, haze, wrinkles, delamination.

- Performance:

(1)Light transmittance ≥90%

(2)Haze ≤0.5%

(3)UV blocking ≥99%

(4)Tensile strength ≥34 MPa

- Secondary Processing: Cutting, drilling allowed with proper tools, avoid heat concentration at edges.

8. Common Issues & Solutions

- Bubbles → insufficient nip/vacuum → increase pressure or extend vacuum time.

- White edges → high humidity or poor splicing → improve humidity control, adjust seam.

- Haze → slow cooling or moist film → optimize cooling, improve storage.

- Delamination → contaminated glass surface or film moisture → strengthen cleaning, humidity control.

9. Storage & Transportation

- Storage: Vacuum-sealed, ≤20 °C, RH ≤30%.

- Shelf life: 12–24 months unopened, use quickly after opening.

- Transport: Shockproof, moisture-proof, avoid sunlight; stack height controlled to prevent deformation.

Product Application

1. Structural & Safety Glass

SGP laminated glass is widely used in high-rise curtain walls, glass facades, and skylights, where superior mechanical strength and impact resistance are required. Compared with traditional PVB laminated glass, SGP interlayers provide higher tear strength and maintain structural integrity even under extreme loads.

2. Hurricane & Seismic Resistant Glazing

In areas with frequent hurricanes, earthquakes, or other natural disasters, SGP laminated glass ensures enhanced protection against flying debris and seismic vibrations, reducing the risk of breakage and ensuring building safety.

3. Balustrades & Canopies

For balustrades, handrails, and overhead glazing systems, SGP interlayers provide long-term stability and transparency. Even if the glass is broken, the interlayer holds fragments firmly, preventing falling hazards.

4. Architectural & Design Applications

SGP's optical clarity and UV resistance make it ideal for applications requiring both safety and aesthetics, such as museums, luxury storefronts, and interior partitions. Its ability to resist yellowing ensures long-lasting visual quality.

5. Transportation & Specialty Glass

SGP interlayers are also applied in railway, marine, and aerospace glazing, where extreme durability, vibration resistance, and long service life are essential.

FAQ

Q1: Can I get a sample before placing an order?

A1: Yes, we provide free samples for quality testing. Customers only need to cover the courier cost. Customized samples are also available upon request.

Q2: What is the minimum order quantity (MOQ)?

A2: Our standard MOQ is usually one full roll per thickness and width specification. For trial orders or new customers, we can be flexible.

Q3: What payment terms do you accept?

A3: We accept T/T (bank transfer), L/C at sight, and other negotiable terms. Typically, 30% deposit is required, with the balance paid before shipment.

Q4: What is your delivery time?

A4: Standard lead time is 7–15 working days after receiving the deposit, depending on order quantity and specifications. Urgent orders can be arranged upon request.

Q5: How do you ensure product quality?

A5: All our EVA films are produced in a dust-free workshop and tested in our technology research center. Each roll undergoes strict inspection for thickness, adhesion, UV resistance, and color stability before delivery.

Q6: Can you produce customized sizes or colors?

A6: Yes, we offer customization for thickness, width, roll length, and colors according to customer requirements.

Q7: How do you package the EVA film?

A7: Films are packed in protective PE film with outer carton or pallet, ensuring safe transportation and long shelf life.

Q8: Which markets do you export to?

A8: Our products are widely exported to Europe, North America, Southeast Asia, and the Middle East, serving both glass processors and construction projects worldwide.

Operation Guide