|

Item |

Unit |

Value / Result |

Remarks |

|

Thickness |

mm |

0.38 / 0.76 |

Standard options |

|

Width |

mm |

2000 / 2400 |

Customizable |

|

Length |

m |

100 (0.38 mm) / 50 (0.76 mm) |

Roll form |

|

Shadowing Rate |

% |

≥ 74.5 (0.38 mm) |

Good light diffusion |

|

Visible Light Transmittance (VL) |

% |

> 24 (0.38 mm) |

Soft translucency |

|

UV Blocking Rate |

% |

≥ 99 (0.38 mm) |

Excellent UV protection |

|

Crosslinking Rate |

% |

> 80 |

Ensures stability |

|

Adhesion with Glass |

N/cm |

> 95 (0.38 mm) |

Strong bonding, no delamination |

|

Tensile Strength |

MPa |

> 18 (0.38 mm) |

High mechanical strength |

|

Weather Resistance |

— |

Pass |

No bubbling or delamination after boiling water (100 °C, 4h) and high humidity/heat (85 °C) tests |

|

UV Aging Test |

ΔYI |

< 1 |

Excellent color stability |

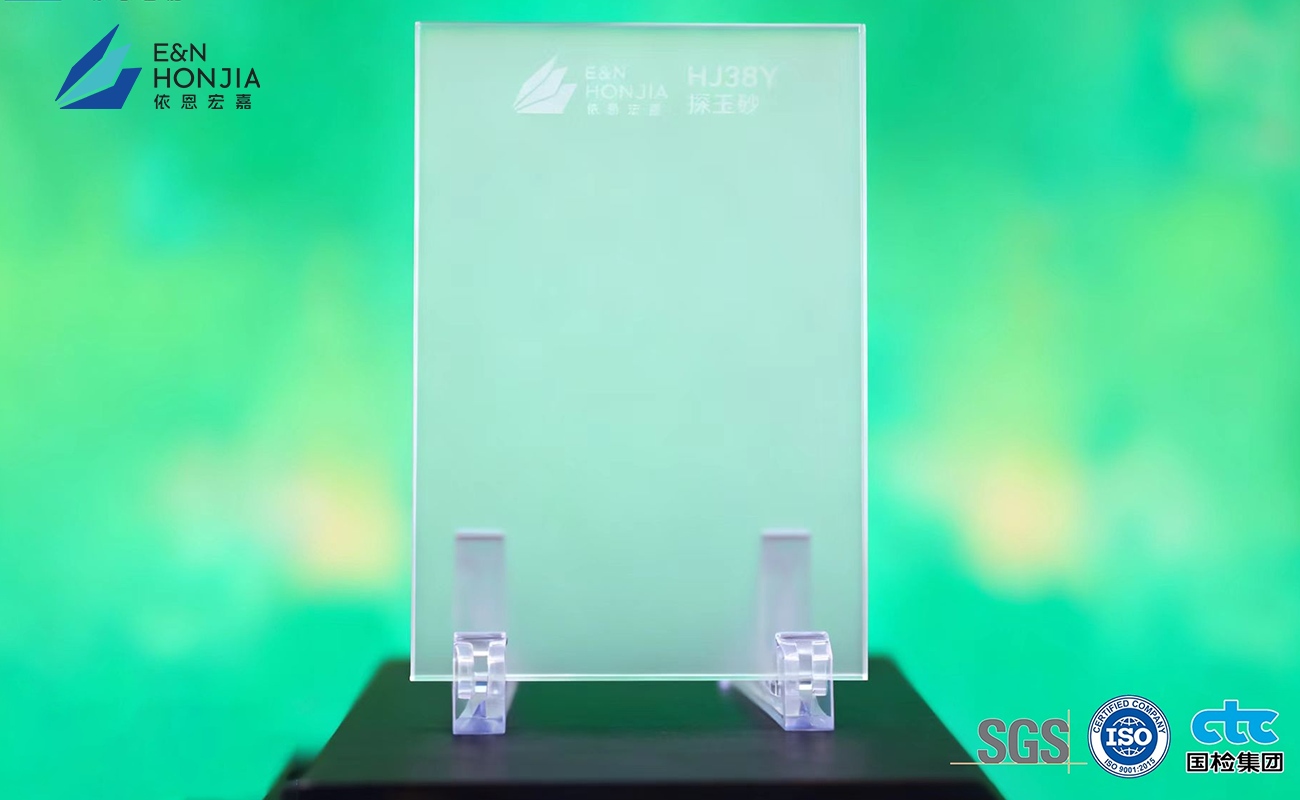

Jade White

Product Features :

- Elegant Jade-White Appearance

- High UV Protection

- Strong Adhesion & Safety

- Durability & Weather Resistance

- Color Stability

- Mechanical Strength

- Flexible Specifications

- Wide Applications

Product Description

The HJ-Y Jade White EVA Film is a high-quality interlayer developed by E&N HONJIA to meet the growing demand for elegant white glass applications in both interior design and architectural projects. With its refined jade-white appearance, the film offers a soft, translucent effect that provides privacy while allowing natural light diffusion, making it highly popular for decorative and functional laminated glass.

Engineered for durability, HJ-Y delivers excellent weather resistance and color stability. It has a crosslinking rate above 80%, strong adhesion with glass (>95 N/cm), and tensile strength exceeding 18 MPa. Even under boiling water tests and high-temperature humidity conditions (85 °C), the film maintains stable performance without delamination, bubbling, or significant color change (ΔYI < 1).

Available in 0.38 mm and 0.76 mm thicknesses with standard widths of 2000/2400 mm, the product offers flexibility for different design needs. At 0.38 mm, it achieves a shadowing rate above 74.5%, visible light transmittance over 24%, and UV blocking over 99%, ensuring both functional protection and aesthetic appeal.

Typical applications include indoor partitions, shower enclosures, and decorative glass façades, where a balance of privacy, light diffusion, and modern style is desired. Its stability under outdoor conditions also makes it suitable for long-lasting architectural and decorative installations.

Product Application

1. Interior Partitions

- Office glass partitions that create private yet bright working spaces.

- Residential partitions that balance openness with privacy.

2. Bathrooms & Shower Enclosures

- Provides privacy while maintaining a modern and stylish look.

- Resistant to humidity and temperature changes, ensuring long-term stability.

3. Decorative & Architectural Glass

- Ideal for decorative façades, curtain walls, and hotel lobbies.

- Enhances design aesthetics with its jade-white, soft translucent appearance.

4. Healthcare & Institutional Buildings

- Suitable for hospitals, clinics, and educational facilities requiring privacy and hygiene.

- Strong adhesion ensures safety by holding glass fragments together in case of breakage.

5. Outdoor Applications

- Performs reliably under UV exposure and harsh weather conditions.

- Long-term color stability makes it a durable solution for outdoor decorative installations.

FAQ

Q1: Can I get a sample before placing an order?

A1: Yes, we provide free samples for quality testing. Customers only need to cover the courier cost. Customized samples are also available upon request.

Q2: What is the minimum order quantity (MOQ)?

A2: Our standard MOQ is usually one full roll per thickness and width specification. For trial orders or new customers, we can be flexible.

Q3: What payment terms do you accept?

A3: We accept T/T (bank transfer), L/C at sight, and other negotiable terms. Typically, 30% deposit is required, with the balance paid before shipment.

Q4: What is your delivery time?

A4: Standard lead time is 7–15 working days after receiving the deposit, depending on order quantity and specifications. Urgent orders can be arranged upon request.

Q5: How do you ensure product quality?

A5: All our EVA films are produced in a dust-free workshop and tested in our technology research center. Each roll undergoes strict inspection for thickness, adhesion, UV resistance, and color stability before delivery.

Q6: Can you produce customized sizes or colors?

A6: Yes, we offer customization for thickness, width, roll length, and colors according to customer requirements.

Q7: How do you package the EVA film?

A7: Films are packed in protective PE film with outer carton or pallet, ensuring safe transportation and long shelf life.

Q8: Which markets do you export to?

A8: Our products are widely exported to Europe, North America, Southeast Asia, and the Middle East, serving both glass processors and construction projects worldwide.