|

Item |

Description |

|

Base Material |

Glass cloth / PET film / Aluminum-glass composite |

|

Adhesive Type |

High temperature silicone adhesive |

|

Temperature Resistance |

Continuous: 200–250 °C; Short-term peak: up to 300 °C |

|

Adhesion Strength |

6–8 N/25 mm (varies by grade) |

|

Tensile Strength |

200–400 N/25 mm |

|

Elongation at Break |

5–10% |

|

Insulation / Resistance |

Excellent resistance to moisture, chemicals, and solvents |

|

Color |

Commonly brown, white, or silver (customizable) |

|

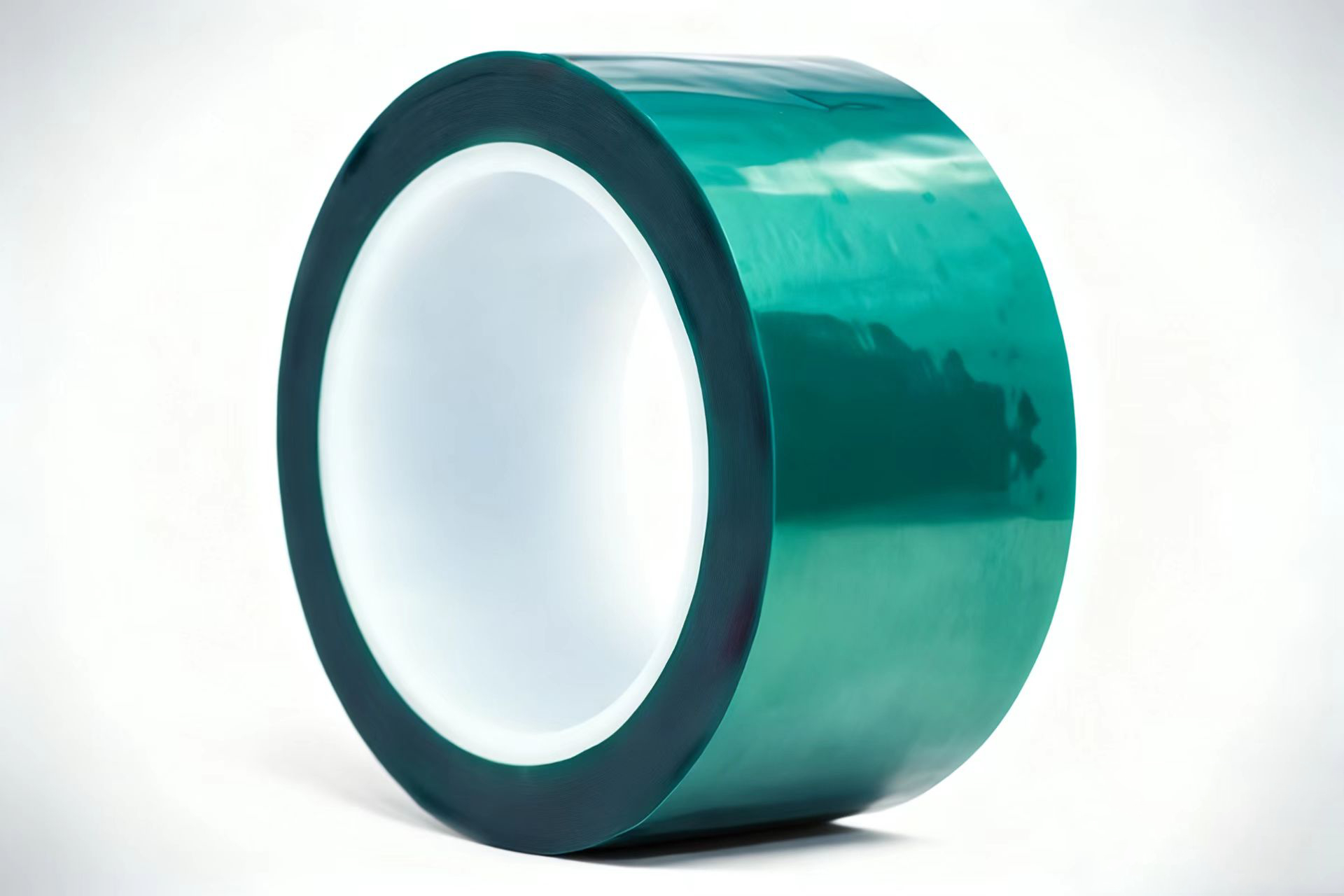

Available Widths |

20 mm – 100 mm (custom sizes available) |

|

Roll Length |

Standard 10–50 m per roll, or customized |

|

Residue |

Clean removal, no adhesive residue after use |

High Temperature Adhesive Tape

Product Features :

- Excellent Heat Resistance – Withstands continuous processing temperatures up to 200–300 °C, ensuring reliable sealing during autoclave and hot-pressing cycles.

- Strong Adhesion & Clean Removal – Maintains firm bonding on glass edges under heat and humidity, yet can be removed easily without leaving residue, reducing cleaning work.

- Dimensional Stability – Reinforced backing (glass cloth, PET, or aluminum composite) prevents deformation, shrinkage, or edge curling during heating.

- Moisture & Chemical Resistance – Resistant to water vapor, resin additives, and chemicals commonly present in laminated glass production.

- Durability in Repeated Cycles – Maintains performance after multiple heating and cooling processes, suitable for mass production lines.

- Customizable Specifications – Available in various widths and lengths to fit flat, curved, and shaped glass production needs.

- Wide Application – Ideal for architectural laminated glass, safety glass, decorative glass, and special glass processing.

Product Description

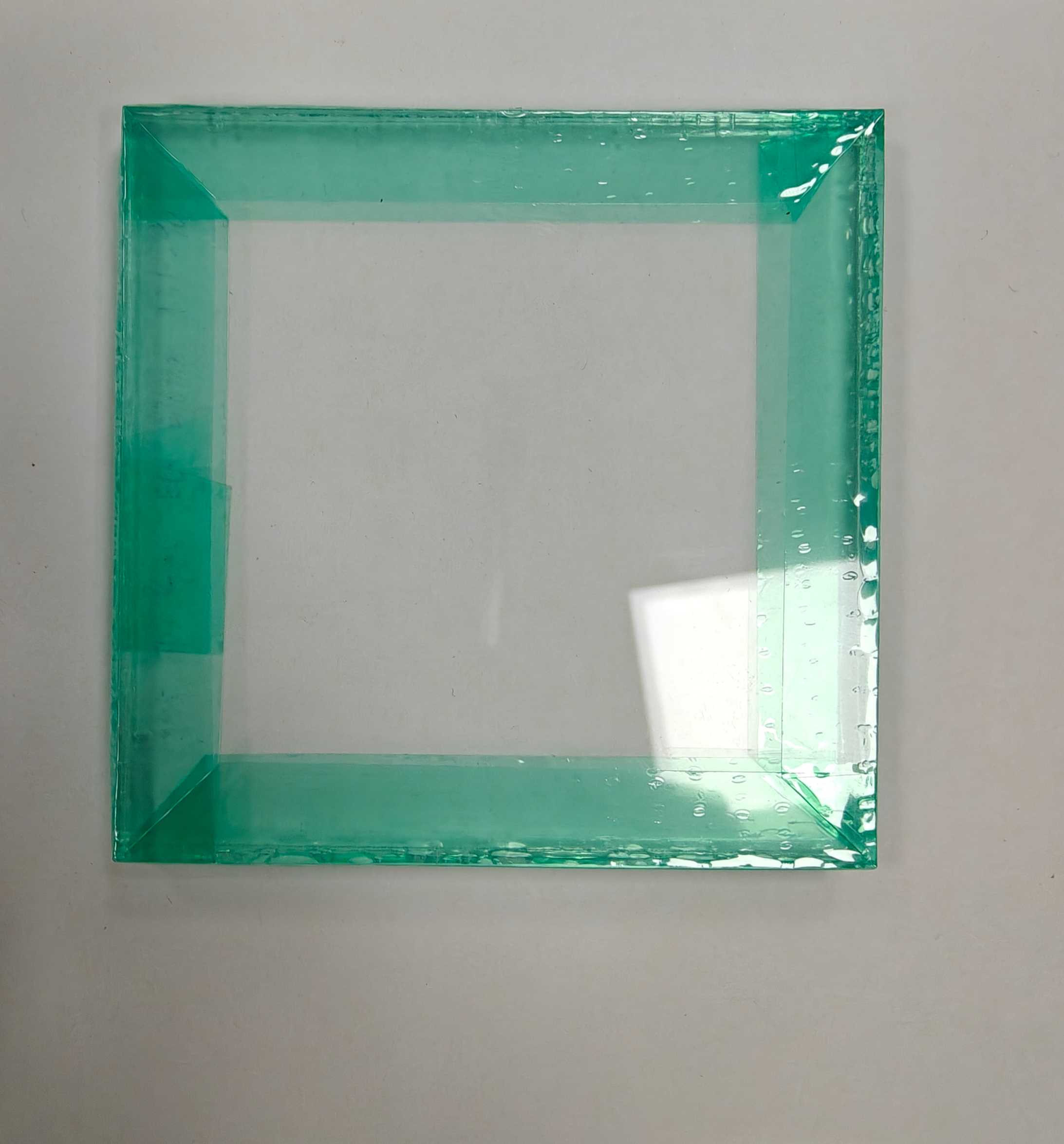

High temperature adhesive tape is a specialized sealing and protection material widely used in laminated glass production. Designed for demanding processing environments, it provides reliable edge protection during autoclave and hot-pressing processes, preventing resin or interlayer materials such as EVA, PVB, or SGP from leaking. Manufactured with heat-resistant substrates like glass cloth, PET, or aluminum-glass composites and coated with silicone adhesive, the tape offers excellent temperature resistance up to 200–300 °C depending on the grade.

This tape combines strong adhesion, stable performance under heat and humidity, and clean removal without residue, ensuring efficient operation and reducing post-processing costs. It also features good chemical resistance, dimensional stability, and durability against repeated heating cycles, making it suitable for architectural laminated glass, safety glass, decorative glass, and curved or special-shaped glass applications.

Available in multiple widths and lengths, high temperature tape can be customized to meet different production requirements. Its balance of heat resistance, sealing reliability, and easy handling makes it an essential accessory for glass manufacturers pursuing high-quality, defect-free laminated products.

Product Application

High temperature adhesive tape is an essential auxiliary material in laminated glass production, providing reliable sealing and protection in various processes:

- Architectural Laminated Glass – Ensures clean edges and prevents resin leakage in curtain walls, windows, doors, and skylights.

- Safety & Security Glass – Used in bulletproof, explosion-proof, and protective glass, keeping interlayers intact during high-temperature lamination.

- Decorative Laminated Glass – Supports lamination with fabrics, paper, colored films, or textured interlayers, guaranteeing neat sealing in creative applications.

- Curved & Special-Shaped Glass – Offers stable adhesion and sealing performance in the production of bent glass, arc glass, and complex shapes.

- Automotive & Transportation Glass – Applied in windshields, partitions, and special safety glass requiring strict sealing quality.

- Public & Specialty Projects – Suitable for laminated glass used in aquariums, glass bridges, and other high-demand structures.

- By combining heat resistance, sealing reliability, and ease of use, high temperature tape provides glass manufacturers with efficient and stable solutions for producing high-quality laminated glass across diverse applications.

FAQ

Q1: What is high temperature adhesive tape used for in laminated glass production?

A1: It is mainly used for edge sealing during autoclave and hot-pressing processes, preventing EVA, PVB, or SGP interlayers from leaking and ensuring clean glass edges.

Q2: What is the maximum temperature resistance?

A2: Depending on the grade, the tape can withstand continuous temperatures of 200–250 °C and short-term peaks up to 300 °C.

Q3: Will the tape leave adhesive residue after removal?

A3: No. High-quality silicone adhesive allows the tape to be removed cleanly without leaving glue residue, reducing cleaning time.

Q4: Can it be used on curved or special-shaped glass?

A4: Yes. The tape has excellent adhesion and flexibility, making it suitable for flat, curved, arc, and irregular glass shapes.

Q5: What specifications are available?

A5: Standard widths range from 20 mm to 100 mm, roll lengths from 10 m to 50 m. Customized sizes are available on request.

Q6: Is it reusable?

A6: No. For best sealing performance and quality assurance, the tape is designed for single-use during each lamination cycle.